Iron / Steel Industry

Businesses in the iron and steel industry require a continuous emission monitoring system to keep their facility within proper emissions regulations. Meeting regulatory guidelines is important for emissions, not only for your facility, but for the safety of your employees and the environment. Having the right emission analyzer is crucial to an efficient and safe workspace. MRU Instruments has emission analyzer options in handheld, portable, and stationary applications for use in the iron and steel industry.

In the iron and steel industry, primary emissions concerns would be carbon dioxide, sulfur dioxide, and nitrogen oxide. However, there are many other gases that are emitted with the creation of iron and steel. Along with gases, a lot of dust is created during iron and steel production. Because of the gases and dust emitted during production, it is extremely necessary to have a combustion analyzer capable of detecting and monitoring multiple gas components. It is also necessary to have a dust opacity monitoring system, like the DM 401 offered at MRU Instruments.

If you need a combustion analyzer, or other continuous emission monitoring system for your iron or steel facility, MRU Instruments has the professional equipment you need. For over 30 years, MRU Instruments has manufactured and distributed our professional emission monitoring systems. Industries of all kinds count on us to deliver efficient products that help create a safer workplace and environment. Browse our iron and steel industry options to find the best fit for your facility today.

-

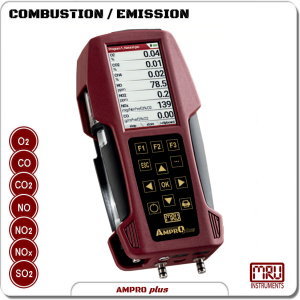

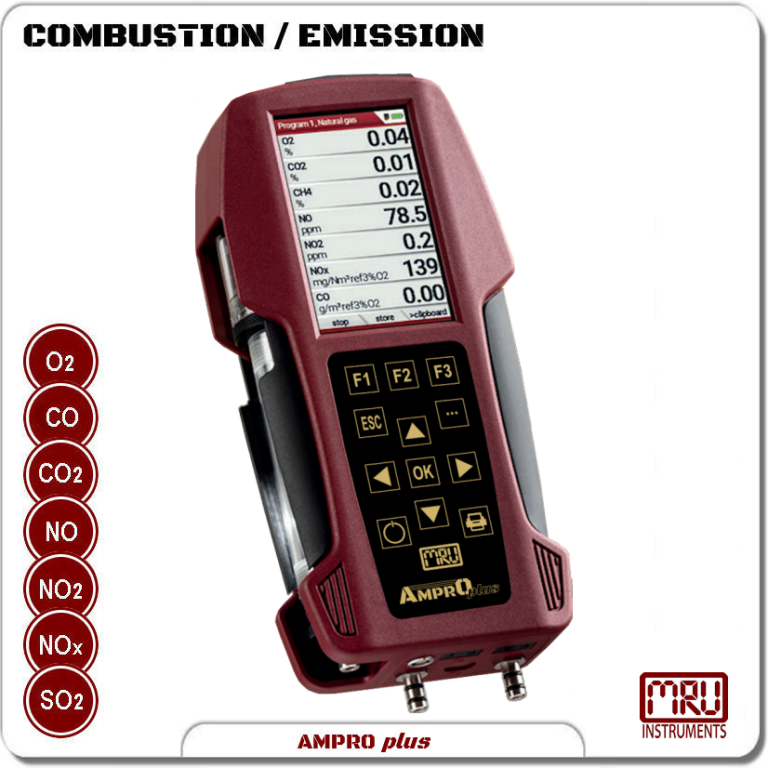

AMPRO plus – Combustion / Emission Analyzer

-

DF 252 Stack Flow Monitor / Transmitter

-

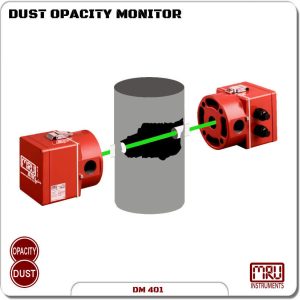

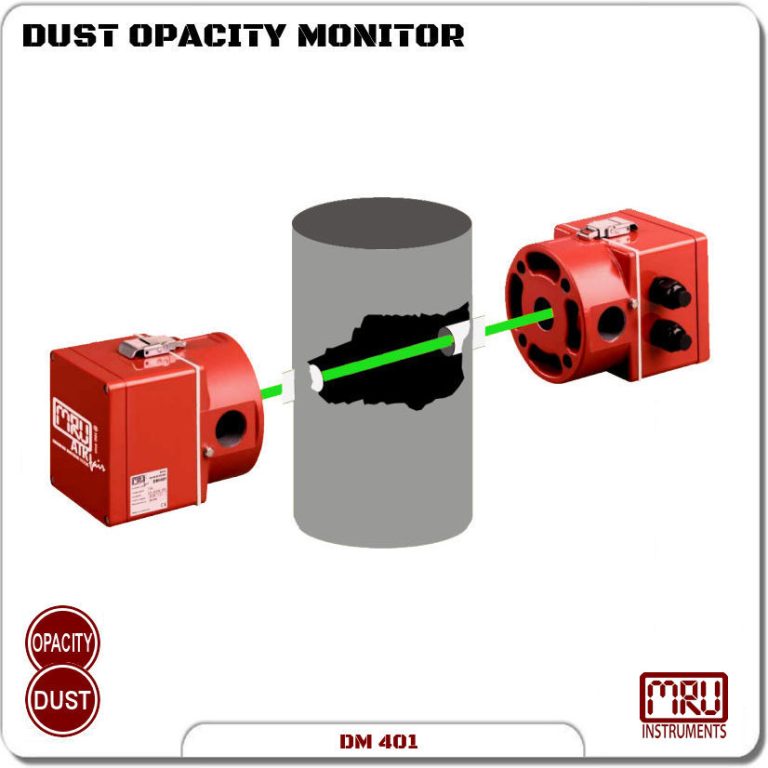

DM 401 – Optical Dust Monitor / Transmitter

-

MGA Prime – Portable Reference Emission Analyzer

-

Multi-Gas Detector 400GD & 500GD

-

NOVA Compact – Combustion Analyzer

-

OMS 420 – Insitu Oxygen / Combustibles Monitor

-

OMS 420 Ex – O2 and COe Monitor

-

OMS 420 HT – Insitu Oxygen / Combustibles Monitor (Hi Temp)

-

OMS 420 RT – Insitu Oxygen / Combustibles Monitor (Remote)

-

SWG 100 CEM – Continuous Emission Monitor

-

SWG 100 SYNGAS – Analyzer

-

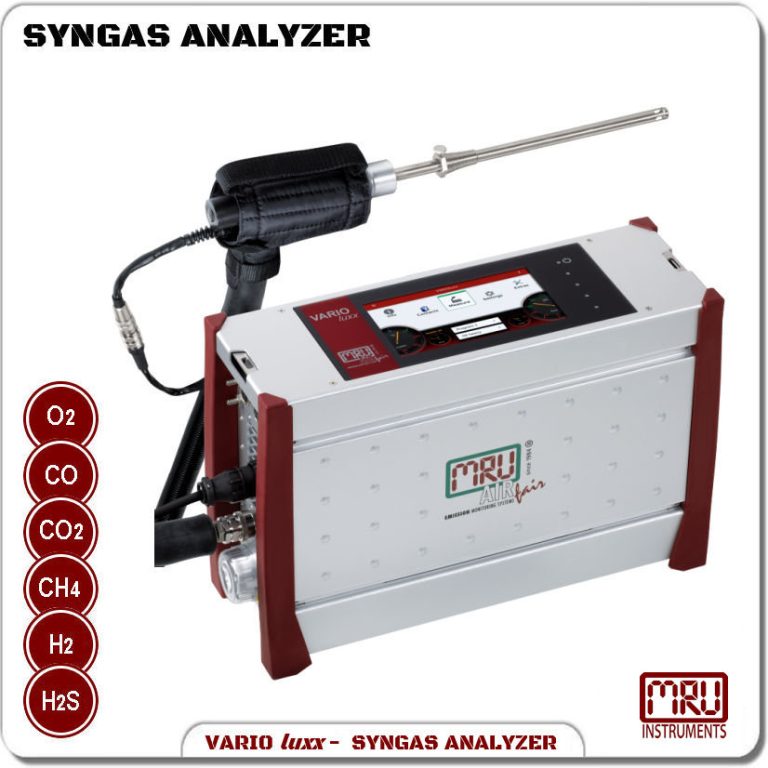

Vario Luxx SYNGAS – Portable Analyzer

-

Take control of your emissions, with the power of our reliable AMPROplus

- Up to 7 gas parameters, plus temperature, pressure, and flow

- +4yr Long-life O2 sensor

- Active CO sensor protection

- Powerful Li-ion battery provides up to 20hrs of operating time

- Extensive probe selection

- Easy Bluetooth connection to the powerful MRU4U App or printer

-

Gas flow velocity and flow rate measurement

- Flow rate calculation (m3/sec) after entering the stack surface.

- With flue gas temperature and absolute pressure measurements

- With optional heater for low ambient temperature and optional blow-back for dusty flue gas

- Unit in weatherproof glass fiber housing

-

DUST OPACITY MONITORING SYSTEM. Double pass opacity monitor. Continuous in-situ measurement.

- Double pass opacity monitor

- Small and light-weight

- Low operating cost

- Minimal maintenance – no moving parts

- Long Life green LED

-

Best-in-class flue gas emission analyzer for long time measurements of industrial combustions

- Precise and very stable non dispersive infrared (NDIR) technique, for enhanced long time measurements.

- Up to 8 gas NDIR measurement

- Remote control via smartphone or tablet

-

TWO compact devices with easy interchangeable sensor heads for multiple applications

- Smart sensor

- Quick change system

- Plug & play sensors with automatic device recognition.

-

Simultaneous measurements of up to 4 gas components

- Very compact and extremely rugged gas analyzer

- Fully equipped for all kind of adjustment and monitoring tasks at combustion

- Intuitively and comfortable to use.

-

In-Situ Oxygen and Combustibles (COe) Transmitter

- All combustions with combustion temperatures up to max. 3,092 °F (1,700 °C) (see different models)

- Die casting aluminum enclosure with electronics, keyboard, up-front display of O₂ and COe*

- COe measurement

- Compressed air back-purge with control valve complete with electronics

-

O2 & COe in-situ monitoring system for use in hazardous area zone 2

- Hazardous area designation of use: Zone 2 or Class 1, Div 2, Gr A/B/C/D

- Special IP 65 pressurized cabinet and z-purge controller, complying to II 3G Ex pz II T3 Gc

- Easy and fast, on site replaceable detector head with sensors (O2 & COe)

- Dust tight and water proof enclosure, with optional ATEX heater for very low ambient air temperatures or optional ATEX Vortec cooler for high ambient temperatures

-

In-Situ real time analysis of Oxygen (O2) and combustibles (COe)

- Model for high temperature

- With automatic back-purge using solenoid valve controlled by transmitter electronics

- With 10m special cable between probe and transmitter

- Die casting aluminum enclosure with electronics, keyboard, up-front display of O₂ and COe*

-

In-Situ real time analysis of Oxygen (O2) and combustibles (COe)

In-Situ real time analysis of Oxygen (O2) and combustibles (COe)- In-Situ real-time analysis of Oxygen (O2) and combustibles (COe)

- Remote transmitter probe

- Model available with and without back purge

-

Stationary Analyzer for Continuous Emission Monitoring

- up to 6 gas simultaneous measurement

- Advanced sample gas preparation for fast and reliable measurements

- Simple installation, ready to run delivery and easy to maintain.

- Heated gas sampling probe

-

Designed for use in industrial safe areas or inside laboratories as well

- IP54 stainless steel cabinet, also for use in outdoor condition with sun and rain cover

- Multiple sampling point monitoring (up to 8 sites monitoring) with one analyzer

- H₂ thermal conductivity detector measurement with cross interference correction

- NDIR bench for CO-CO₂-CH₄ analysis (using selective CH₄ measurement)

- H₂S electrochemical cell measurement, H₂ immune

- Sample gas washing device, for tar free sample gas

-

Portable syngas analyzer for long-term measurements of special gases (syngas)

- Integrated electrical gas cooler (Peltier) and automatic condensate draining pump

- Strong sample gas pump and externally accessible particulate Teflon filter

- Use of long-life EC cell for O2, NDIR for CO/CO2/CH4 and TCD for H2 measurement

- Linux OS and large back-lit 840x480 px color display, with touch and swipe technique

- n Lithium-ion battery operation, including gas cooler and measurement technology

No products found