Description

Features:

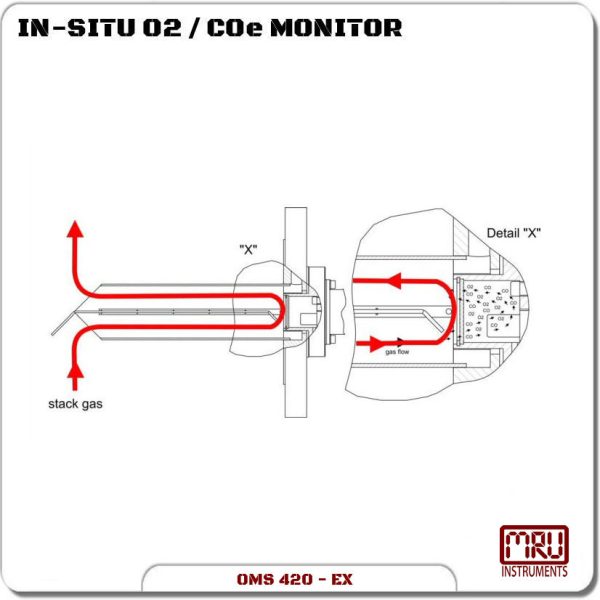

- O2 & COe in-situ monitoring system for use in hazardous area zone 2

- The O2 and COe monitor is dedicated for continuous combustion optimization at:

- Various industrial furnaces/ovens/boilers, with hazard of explosive atmosphere

- Petroleum refinery plants petrochemical plants

- Gas separation, blast furnace, coke oven, or other syngas plants

Benefits:

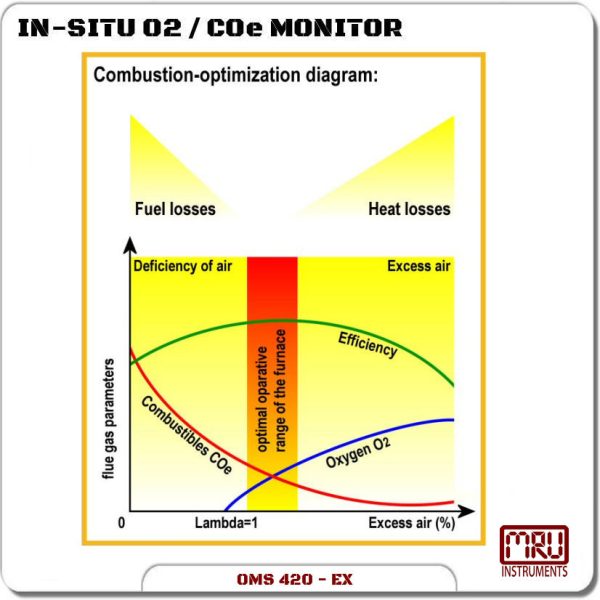

- Make your combustion process more cost-effective.

- Get the data to show your organization cares about the environment.

Applications:

Cement Industry, COe, Continuous Emission Monitoring, Gas Turbines / Compressor, IN-SITU, Installers / Boiler Manufacturers, Iron / Steel Industry, O2, Power Plants, Refineries / Petrochem, simple