Boiler / Burner / Furnace

All manufacturing facilities require a continuous emission monitoring system in place to stay within regulatory guidelines. Along with emission regulations, a gas analyzer will allow your facility to come up with ways to cut down on emissions to maintain the safety of employees and the environment. In boiler manufacturing and installing, emission monitoring systems are incredibly important. MRU Instruments has a great selection of handheld, portable, and stationary gas analyzer options for the boiler manufacturing and installing industry.

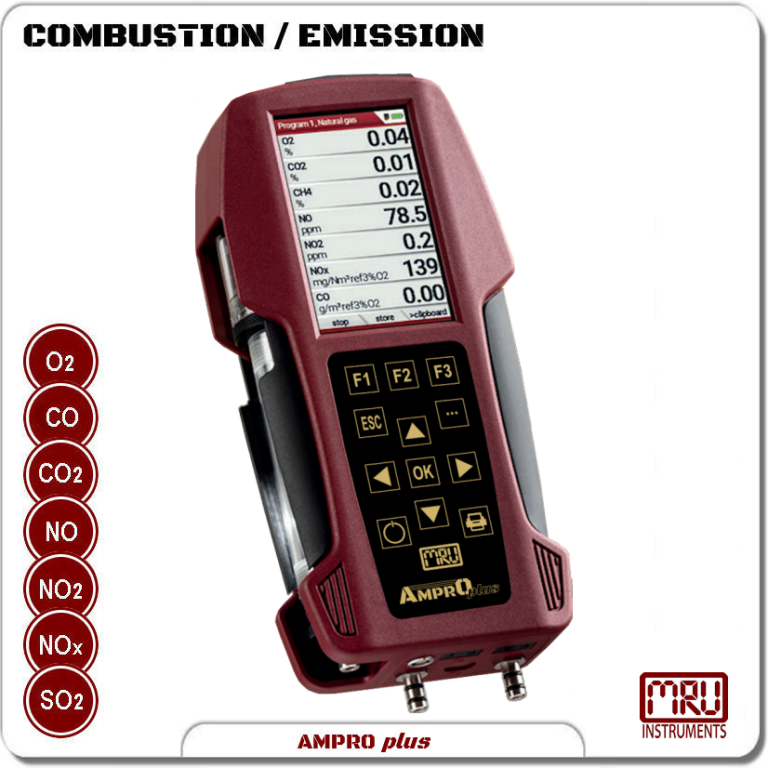

A combustion analyzer is important to detect and locate gas leakages in boilers. The AMPRO plus is a great option as a handheld and portable combustion analyzer from MRU Instruments. We also carry the NOVA Compact and NOVA Plus combustion and emission analyzer capable of detecting up to 8 gas components. These emission monitoring systems are perfect for the boiler manufacturing and installing industry. When you need to meet regulations and keep emissions down in the environment, MRU Instruments is here to help.

In industries where gas components are constantly in the environment, it is a great idea to invest in a continuous emission monitoring system for your facility. MRU Instruments has been manufacturing and distributing our professional line of emission monitoring systems for over 30 years. With our gas analyzers, you are guaranteed efficient performance. Shop our selection of emission analyzers for your industry today.

-

AMPRO 1000 – Combustion Analyzer

-

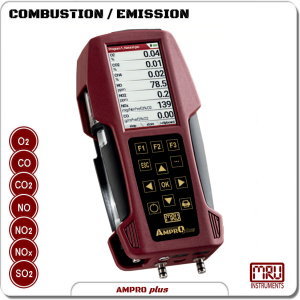

AMPRO plus – Combustion / Emission Analyzer

-

DM 9600 – Manometer / Pressure Meter

-

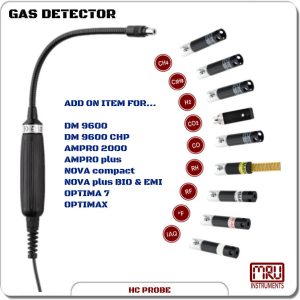

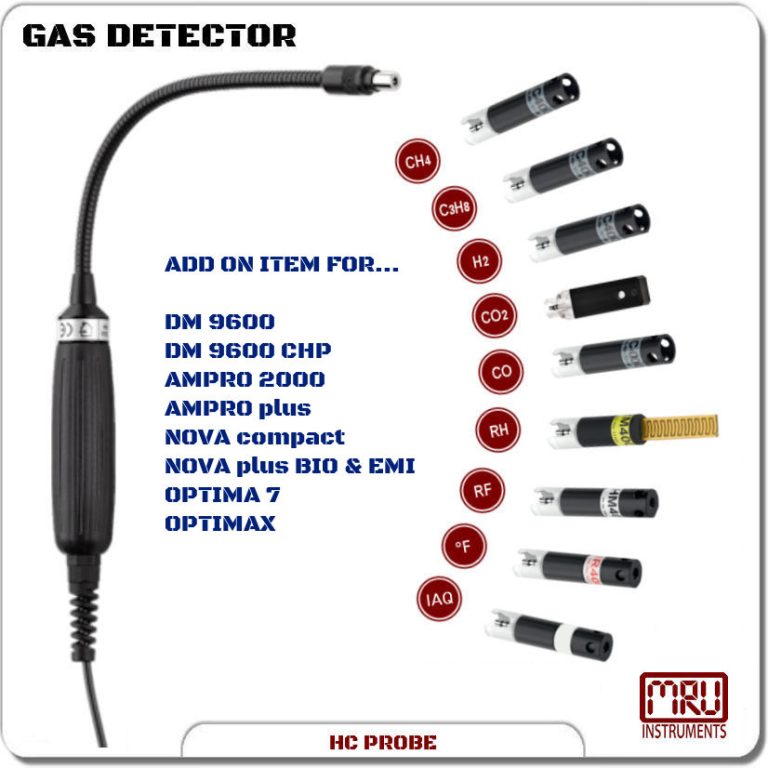

Gas Detector / Gas Sniffer Probe

-

Multi-Gas Detector 400GD & 500GD

-

NOVA Compact – Combustion Analyzer

-

NOVA Plus – Portable Emission Analyzer

-

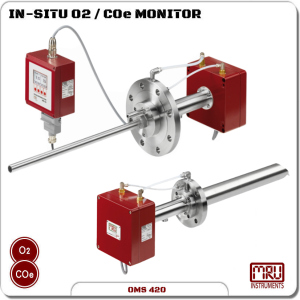

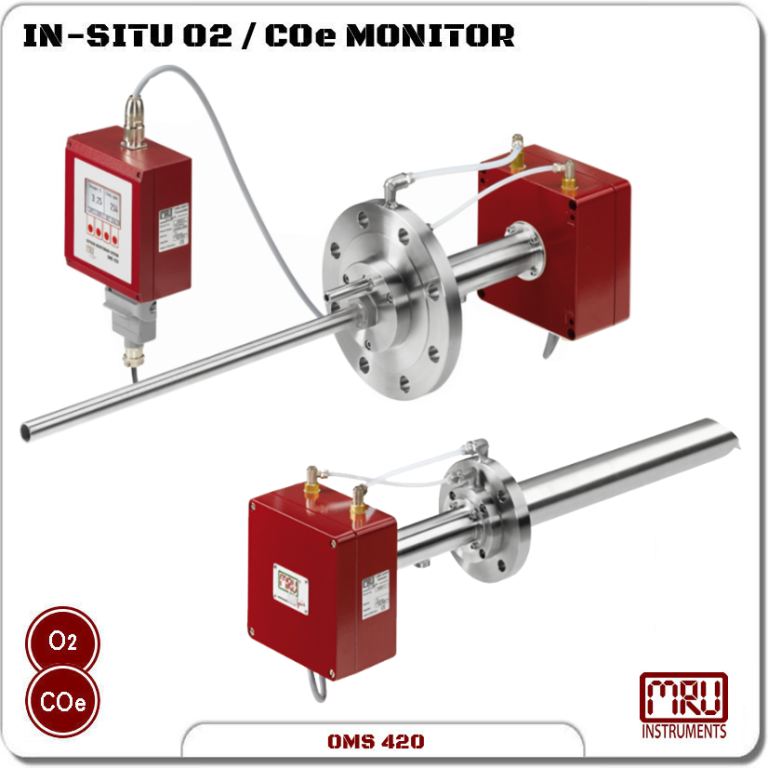

OMS 420 – Insitu Oxygen / Combustibles Monitor

-

Low cost combustion analyzer

Low cost combustion analyzer- For control measurements at gas-, oil- and wood-firings

- Flue gas analyzer with real-time combustion calculation

- Digital manometer for stack draft and differential pressure

- Ambient air CO tester

-

Take control of your emissions, with the power of our reliable AMPROplus

- Up to 7 gas parameters, plus temperature, pressure, and flow

- +4yr Long-life O2 sensor

- Active CO sensor protection

- Powerful Li-ion battery provides up to 20hrs of operating time

- Extensive probe selection

- Easy Bluetooth connection to the powerful MRU4U App or printer

-

Versatility Redefined: The Pressure Manometer Analyzer - Your Ultimate Multifunctional Tool!

- Precision multi-functional manometer

- FIVE different models

- Ranges +/- 3″ H2O to 100 PSI

- Accuracy to 0.5%

- Bluetooth, USB, IR and SD card interfaces

-

Reliable gas leak detection and stack moisture detection with just one system

- Sensor exchange during operation

- Adjust alarm threshold.

- Works with AMPROplus/ OPTIMAX/ DM9600

-

TWO compact devices with easy interchangeable sensor heads for multiple applications

- Smart sensor

- Quick change system

- Plug & play sensors with automatic device recognition.

-

Simultaneous measurements of up to 4 gas components

- Very compact and extremely rugged gas analyzer

- Fully equipped for all kind of adjustment and monitoring tasks at combustion

- Intuitively and comfortable to use.

-

Simplify compliance testing and ensure success with our dependable, user-friendly combustion emissions analyzer

- Combination of infrared measurement technology and electrochemical sensors

- Automatic measuring program with data recording

- Automatic zero-point measurement for long-term measurements

-

In-Situ Oxygen and Combustibles (COe) Transmitter

- All combustions with flue gas temperatures up to max. 3,092 °F (1,700 °C)

- (4 different models, Compact / RT / HT & EX)

- Die casting aluminum enclosure with electronics, keyboard, up-front display of O₂ and COe*

- COe measurement without the need of dilution

- Compressed air back-purge for RT / HT and EX model

No products found