Description

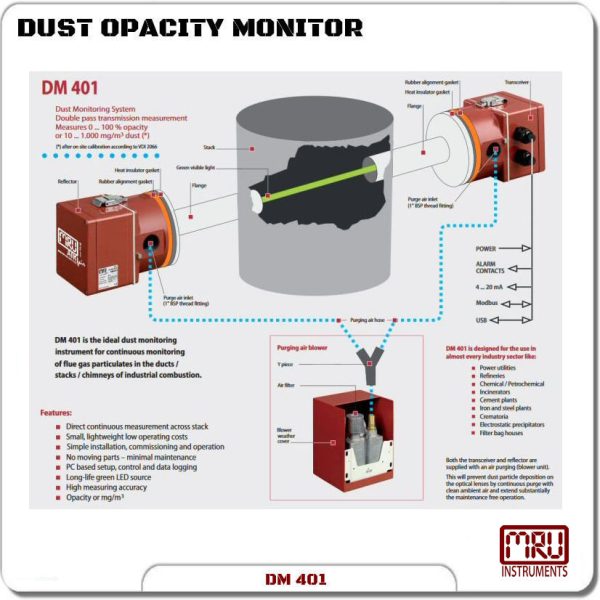

Features:

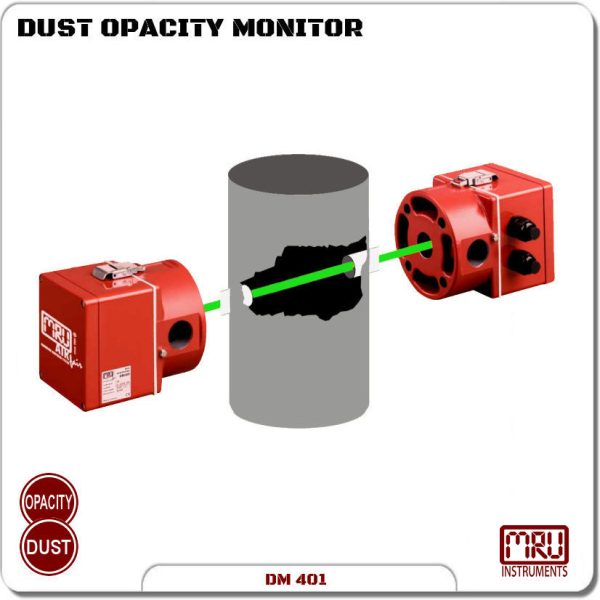

- Double pass opacity monitor

- Small and light-weight

- Low operating cost

- Minimal maintenance – no moving parts

- Long Life green LED

Benefits:

- Make your combustion process more cost-effective.

- Get the data to show your organization cares about the environment.

Applications:

Stack opacity, Stack dust monitoring, Emission opacity, baghouse dust monitor, Continuous Emission Monitoring, Flow / Dust, Gas Turbines / Compressor, Iron / Steel Industry, Power Plants, Refineries / Petrochem, simple

Measurement performance

| Parameter |

Units |

Min |

Max |

Comment |

| Path. length (flange to flange) |

meters |

0.5 |

10 |

flange-to-flange distance |

| Measuring range |

|

|

|

|

| Particulate |

mg/m³ |

10.0 |

1000 |

after on site calibration |

| Opacity |

% |

0.0 |

100.0 |

user selectable |

| Accuracy |

% |

–2 |

+2 |

|

| Resolution |

mg/m³ |

|

0.1 |

display resolution |

| Damping |

s |

1 |

60 |

selectable |

| Drift with temperature |

% |

–2 |

+2 |

for any 20 °C change |

| Operating wave length |

nm |

510 |

540 |

green LED |

Power and air requirements

| Voltage |

Vdc |

|

+24 |

90 … 240 Vac PSU available |

| Air supply volume |

l /min |

50 |

200 |

to each air purge inlet |

| Air supply fitting |

|

|

|

1″ BSP threaded aperature |

Interface options

| RS 485 |

|

|

|

ModBus RTU |

| Analog outputs |

mA |

4.0 |

20.0 |

isolated and scalable |

| Relay contact |

3 A @ 30 Vdc |

|

|

level alarm and service alarm |

Physical

| Protection class |

|

|

IP 65 |

for outdoor use |

| Operating temperature |

°C |

–20 |

+55 |

air temperature around the equipment |

| Gas temperature |

°C |

100 |

600 |

heat insulated gaskets included |

Dimensions

| Transceiver |

6.02” x 4.8” x 4.72” |

153 x 122 x 120 mm |

| Reflector |

6.02” x 4.8” x 4.72” |

153 x 122 x 120 mm |

| Purging air blower unit |

12.2” x 8.66” x 9.05” |

310 x 220 x 230 mm |

| Enclosure |

|

stainless steel, powder coated |

| Weight |

transceiver: 5.5 lbs., reflector: 5.5 lbs. purging air blower unit: 24 lbs. |

transceiver: 2,5 kg, reflector: 2,5 kg purging air blower unit: 11 kg |