Description

| ANALYZER COMPARISON CHART | BIOGAS ANALYZER | BIOGAS ANALYZER UL LISTED | LANDFILL ANALYZER | BIOGAS METHANE ANALYZER |

|---|---|---|---|---|

| STANDARD ANALYZER CONFIGURATION | # 951002 | # 951006UL | # 951002LFG | # 951030 |

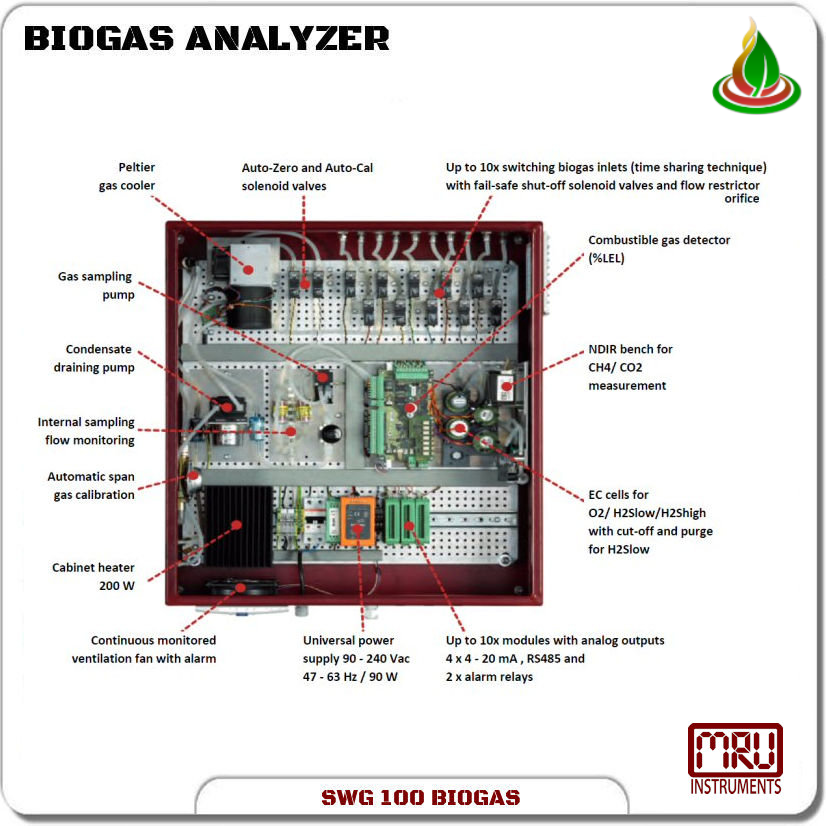

| regulated sample gas pump with sample gas flow monitoring and adjustment | ✅ | ✅ | ✅ | ✅ |

| filtration of sample gas and of acid gases before internal sample flow sensor | ✅ | ✅ | ✅ | ✅ |

| sampling from low suction -100mbar up to +250mbar (including OPTION 12652) | ✅ | ✅ | ✅ | ✅ |

| solenoid valve for auto-zero (with clean ambient air) and for automatic calibration using permanently attached gas mixture cylinder (user scope of supply) | ✅ | ✅ | ✅ | ✅ |

| sample gas supply cut-off in case of system alarm, using “fail-safe” solenoid valve (normally closed), including one sample gas sampling inlet port | ✅ | ✅ | ✅ | ✅ |

| all stainless steel gas connectors 1/8”ID threads, with 6mm bulkhead compression fittings (also replaceable by user) | ✅ | ✅ | ✅ | ✅ |

| stainless steel adapter 1/8”I – 1/8”O, with flow restrictor orifice, to be mounted at sample gas inlet from high pressure sampling | ✅ | ✅ | ✅ | ✅ |

| human machine interface with color TFT display, keyboard and RS485 interface (Modbus RTU) | ✅ | ✅ | ✅ | ✅ |

| all password protected, intuitive software guided menu, with diagnosis software and logbook | ✅ | ✅ | ✅ | ✅ |

| External Main Switch | ❌ | ✅ | ❌ | ❌ |

| UL Certified | ❌ | ✅ | ❌ | ❌ |

| ON SITE START UP SUPPORT (UL MANDATORY) | ❌ | ✅ | ❌ | ❌ |

| Dilution system 1:50 for continuous measurement of H2S sample gas | ❌ | ❌ | ✅ | ❌ |

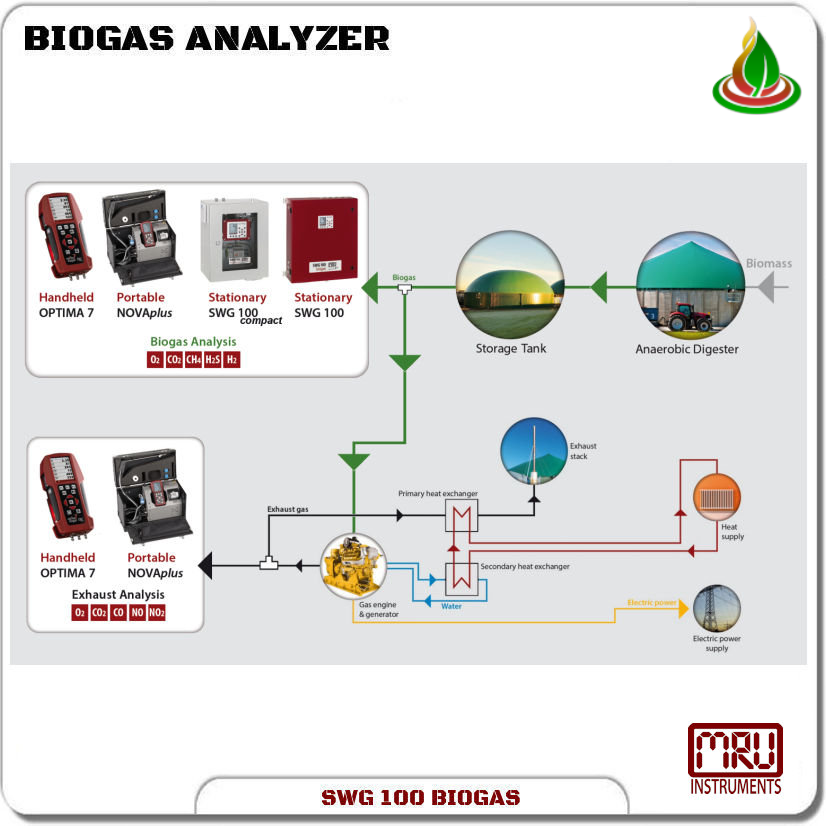

Features:

- Stationary biogas analyzer

- Analyzer for biogas, bio-methane, landfill-gas, coal bed methane

- Customizable for your needs and applications!

Benefits:

- Make your biogas process more cost-effective.

- Get the data to show your organization cares about the environment.

Applications:

Bio Gas / Landfill / CHP, Biogas / Landfill / CHP, CH4, CO, CO2 Measured, H2, H2S, O2, simple