A manometer is a gadget that measures pressure with a section of fluid. A basic manometer comprises a U-formed cylinder that contains a fluid. On the off chance that the pressing factor is distinctive between the two closures of the cylinder, the fluid will move away from the wellspring of a more noteworthy pressing factor. The guidelines that follow accept one side of the cylinder is available to the air, and a wellspring of positive pressing factor is associated with the opposite side. For the most precise readings on the manometer, deal with specific things alongside its estimating strategies.

Measure the distance between the fluid’s present level on one side and its set up zero focus, which might be shown by an imprint on the cylinder. Increase this distance by 2, in light of the fact that the outside of the fluid on the right goes somewhere near the very distance that the left side goes up; the complete distance of the fluid development is, accordingly, double the deliberate development of one side.

Decide the pressing factor in water inches. Accepting the fluid in the manometer is water, this is essentially the consequence of stages 1 in inches. Albeit non-standard, this is a typical proportion of pressing factors since it very well may be dictated by direct estimation.

In the first place, convert the non-metric estimations to metric ones. Then, at that point, convert the manometer perusing to standard units of pressing factor. Utilize the standard recipe p = d * h * 9.8 where “p” is the pressing factor in pascals, “d” is the thickness of the fluid in the cylinder in kilograms per cubic meter, “h” is is the doubled height difference in meters from stage 1 and 9.8 is the descending power of gravity, 9.8 meters each second squared. So on the off chance that you measure a stature contrast of .01 meters, twofold it to .02, duplicate by 1,000 kg for every cubic meter for water, and increase by 9.8 to get 196 pascals of pressing factor.

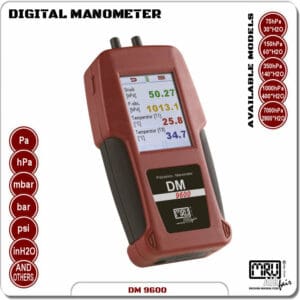

It is necessary to rely upon a high-edged manometer like the ones with MRU Instruments so that you never go wrong with your measurements.