Description

Features:

- Complete CEM system for emissions monitoring

- The multi-component gas analyzer SWG 300-1 is based on extractive, cold-dry method

- The SWG 300 can measure up to 8 gas components, using MRU optimized NDIR technology, with improved accuracy and without zero offset.

- Oxygen analysis using, paramagnetic cell or “long-life” electro-chemical cell.

Available as:

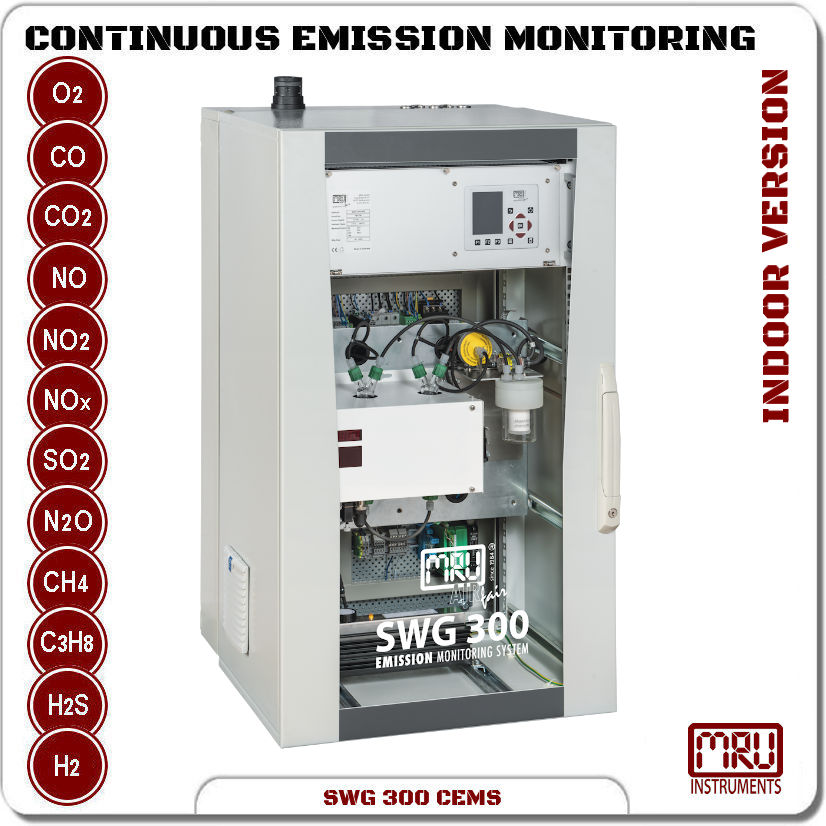

- SWG 300 INDOOR

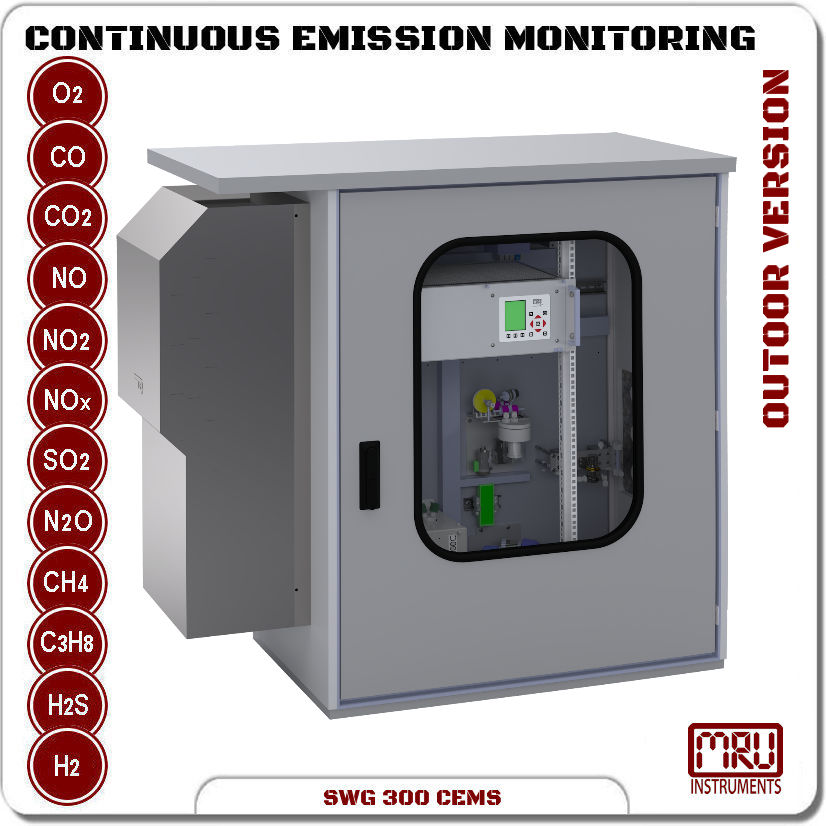

- SWG 300 OUTDOOR

- SWG 300 EX-ZONE 2

Benefits:

- High End Stationary Continuous Emission Monitoring system.

- Improved accuracy and without zero offset.

Applications:

Coal power stations, Municipal and other waste incinerators, Cement outlet stacks, Glass melting industry, Solid fuels and heavy oil combustion sites, Bagasse and biomass steam boilers, and others.