Description

| OMS COMPARISON CHART | OMS COMPACT | OMS RT | OMS HT | OMS EX |

| ZrO2 sensor for wet O2 analysis | ✅ | ✅ | ✅ | ✅ |

| Heated solid electrolyte sensor for combustibles | OPT | OPT | OPT | OPT |

| DN65 PN6 flange | ✅ | ✅ | ✅ | ❌ |

| 4″ANSI 150lbs flange |

OPT | OPT | OPT | ✅ |

| Compact probe with flow guidance (hollow) tube | ✅ | ✅ | ❌ | ✅ |

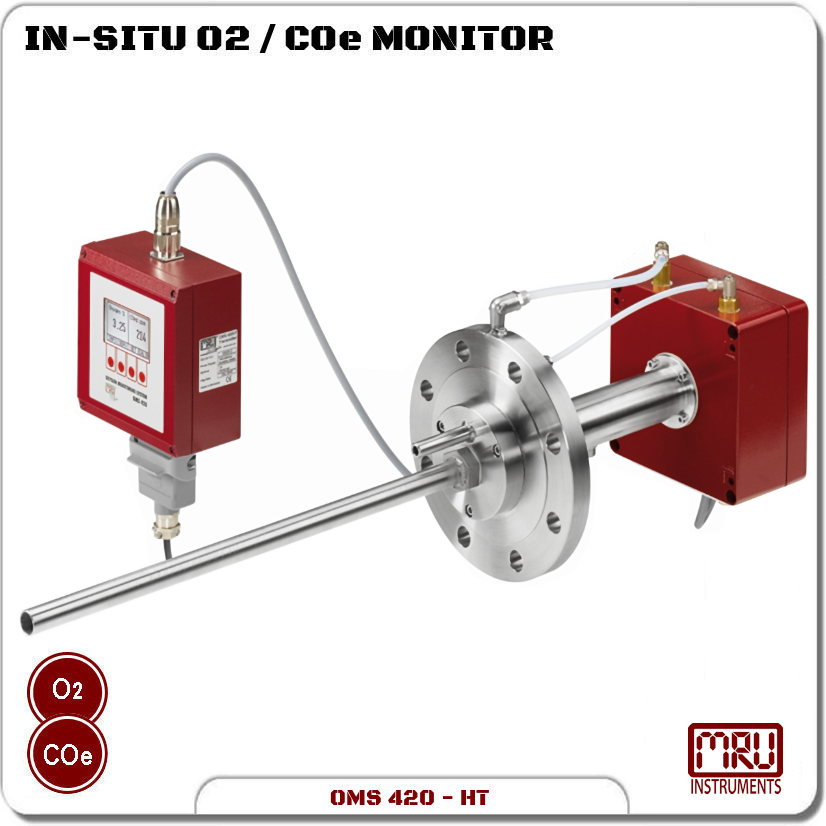

| Ejector tube, needing compressed air | ❌ | ❌ | ✅ | ❌ |

| Back-purge for sensors and probe | ❌ | OPT | ✅ | OPT |

| Flue gas temperature | ≤1800°F | ≤1800°F | ≤3000°F | ≤1800°F |

| Transmitter with microprocessor, graphical LCD | ✅ | ✅ | ✅ | ✅ |

| IP 65 | ✅ | ✅ | ✅ | ✅ |

| Integrated auto-calibration | ❌ | OPT | OPT | OPT |

| Reference air inlet through natural diffusion, no air pump is required | ✅ | ✅ | ✅ | ✅ |

| 2x analog 4-20 mA galvanic isolated | ✅ | ✅ | ✅ | ✅ |

| Digital RS 485 with Modbus RTU protocol | ✅ | ✅ | ✅ | ✅ |

| Hazardous area designation of use: Zone 2 or Class 1, Div 2, Gr A/B/C/D | ❌ | ❌ | ❌ | ✅ |

| Special IP 65 pressurized cabinet and z-purge controller, complying to II 3G Ex pz II T3 Gc | ❌ | ❌ | ❌ | ✅ |

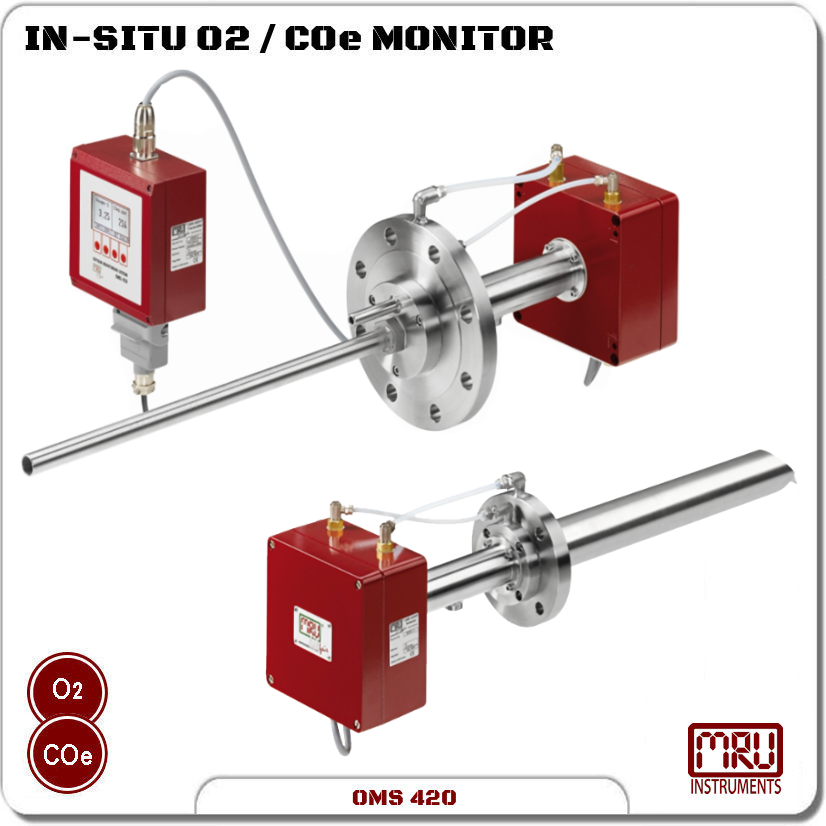

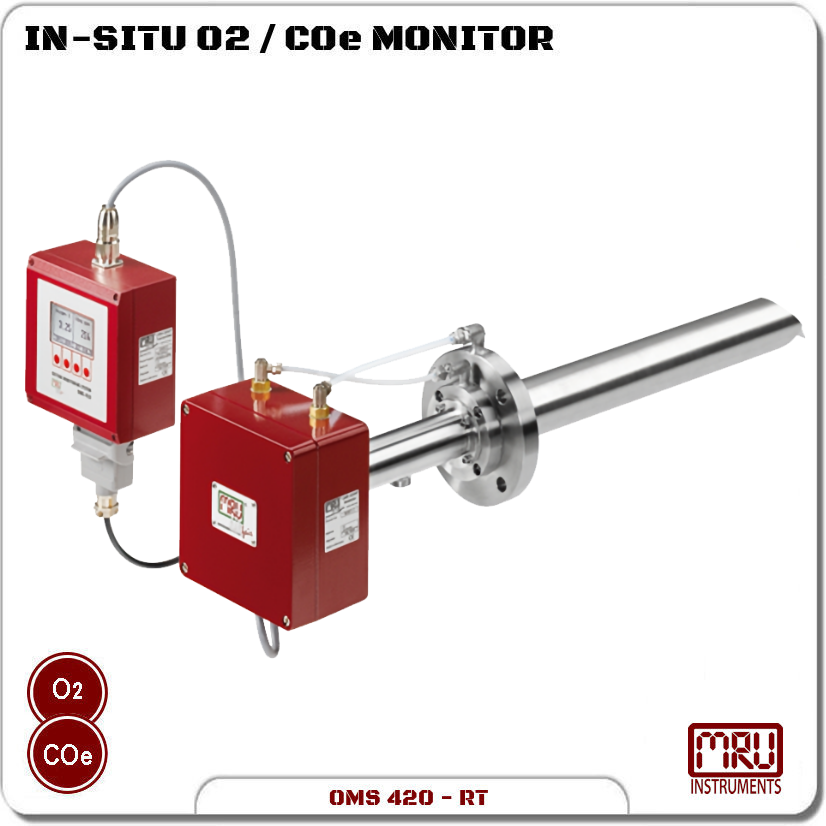

Features:

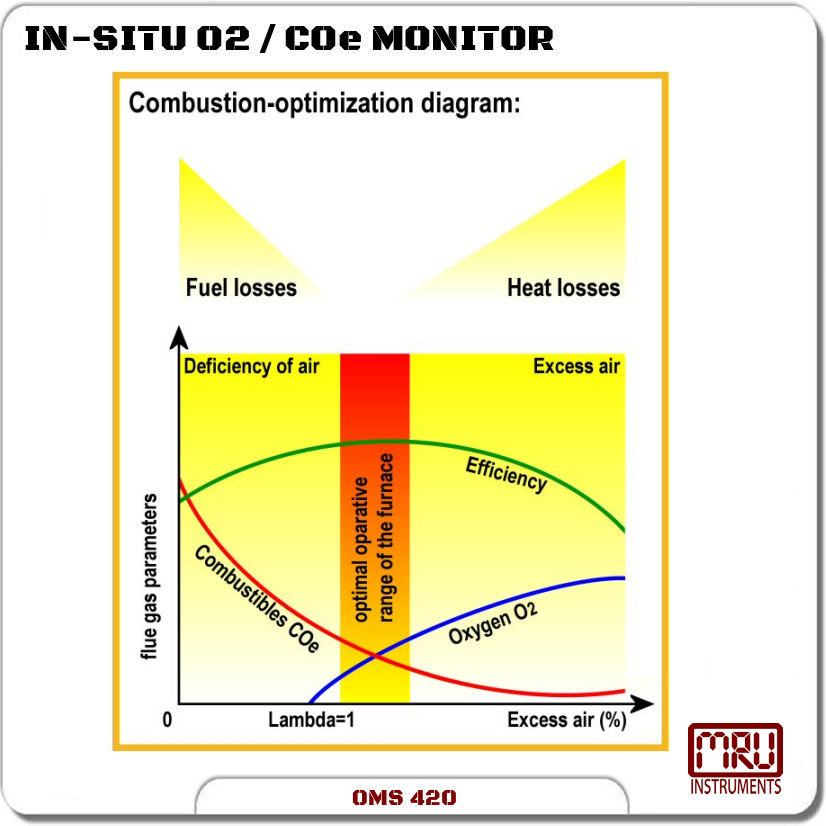

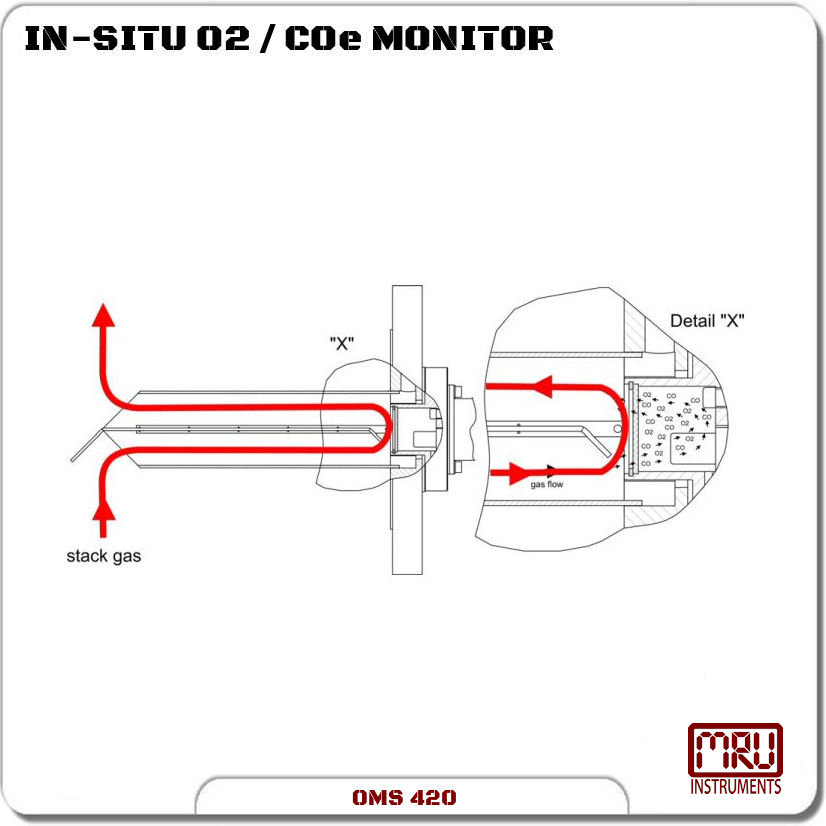

- In-situ combustion optimization monitor

- Oxygen and Combustibles (COe) Transmitter

- combination of O2 and COe for ideal combustion efficiency

- Superior Design for Superior Results!

- Real-time measurements

- Unique, heated solid electrolyte combustibles sensor

- Easy access to sensors for fast and simple service

Benefits:

- Make your combustion process more cost-effective.

- Get the data to show your organization cares about the environment.

Applications:

Gas Turbines / Compressor Stations / Boiler Manufacturers / Iron & Steel Industry / Power Plants / Refineries / Petrochem