Description

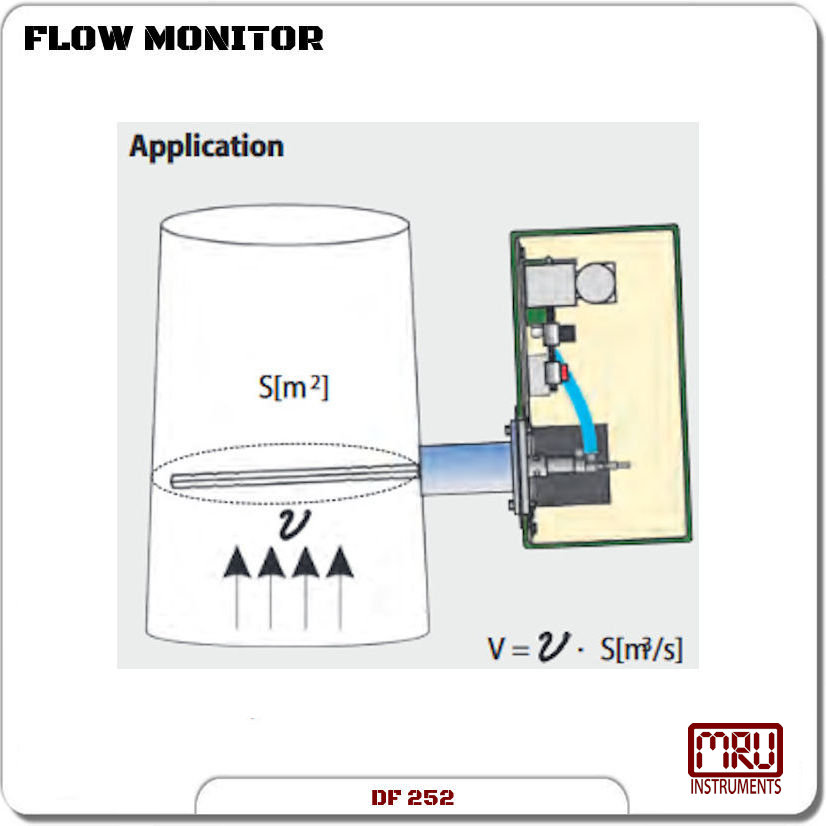

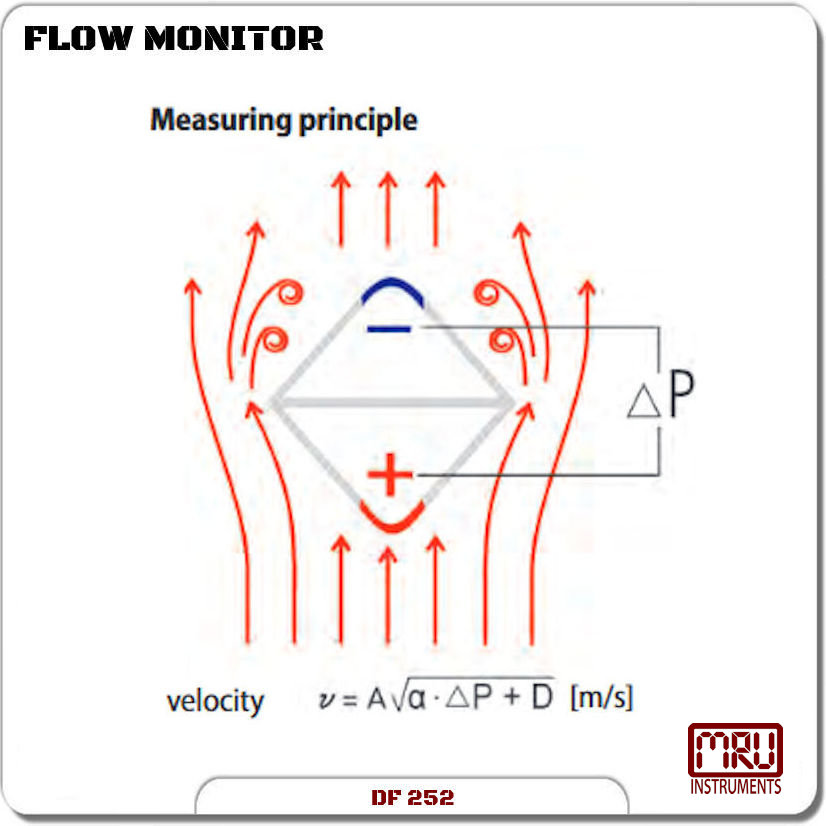

Flow rate measurement using the dynamic pressure measurement principle

Features:

- Continuous measurement of flow velocity of flue gas and air streamings

Benefits:

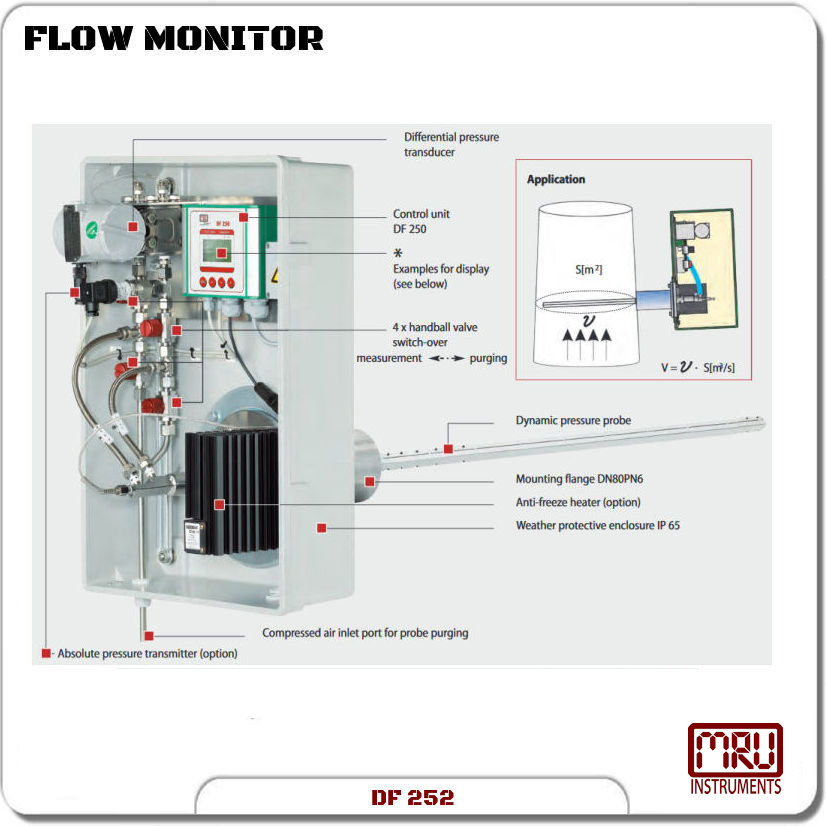

- Compact system of probe and control device, therefore easy installation

- On-site diagnosis of the facility’s state due to a graphical display with high resolution showing on-line diagram

- Display of flow in norm state (i.n.) or operating state (i.o.) possible

- Display options in mbar, m/s, m³/h i.o. or m³/h i.n. as well as °C

- Display of absolute pressure in mbar optionally possible

- Simple installation with DN80PN6 flange for welding

- Low maintenance, handball valves for probe back-purging

Applications:

For the operation of a facility with streaming gases (e.g. flue gas, air, etc.) the continuous registration of the exhaust gas

velocity respectively the flow as well as the temperature are often of substantial importance.