Description

Features:

- Designed for use in industrial safe areas or inside laboratories as well

- Can be installed in outdoor or indoor location

- Can sample dry or wet syngas

- Can sample pressurized or low pressure gas

- Can be used from single or double sampling points.

Benefits:

- Make your combustion process more cost-effective.

- Get the data to show your organization cares about the environment.

Applications:

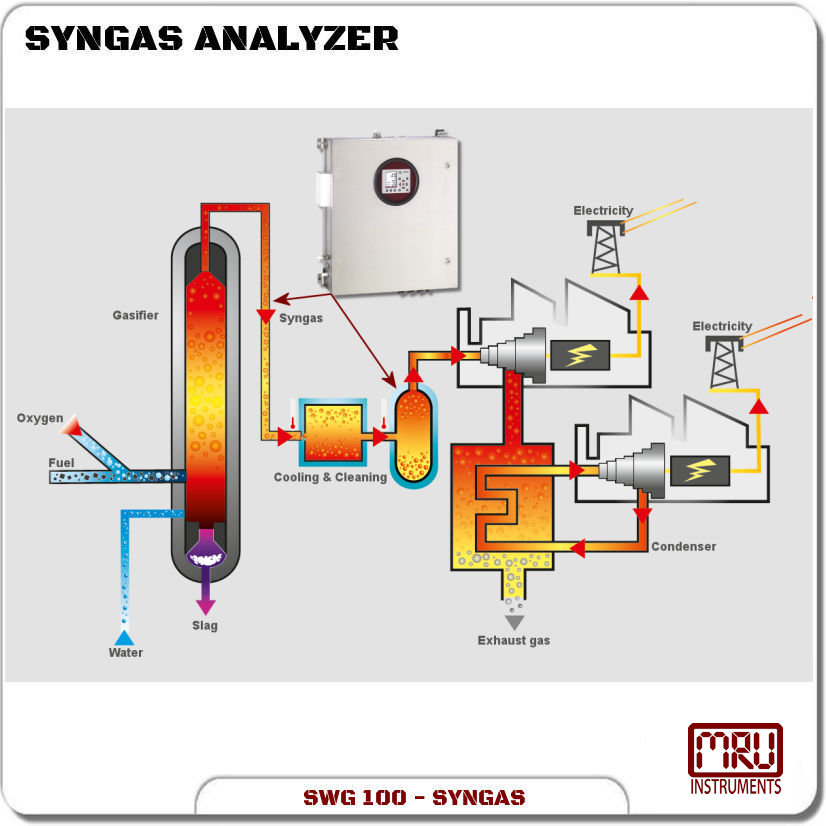

Biomass, coal and waste gasification plants

Co-generation heat and power engines (CHP) using syngas

Small scale syngas analysis for research institutes and labs

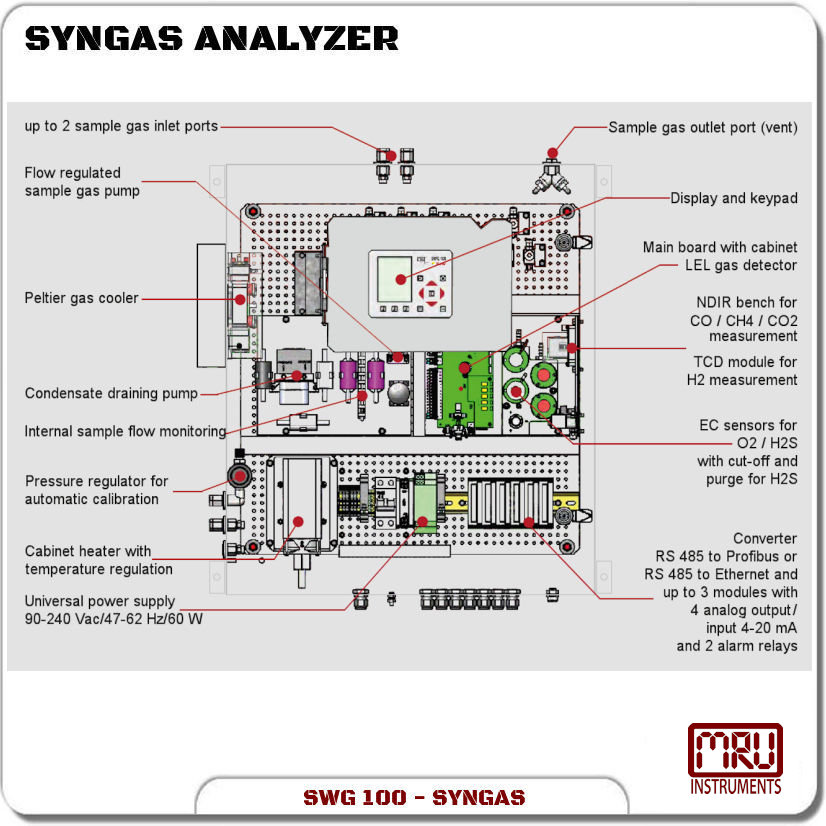

The complete, ready to use analyzer SWG100 Syngas

is the industrial solution for:

- biomass, coal and waste gasification plants

- cogeneration heat and power engines (CHP) using syngas

- small scale syngas analysis for research institutes and lab

WITH

- IP 54 stainless steel cabinet, also for use in outdoor conditions with sun and rain cover

- accurate measurements, using infrared and thermal conductivity technology

- sampling from low suction -100mbar up to high pressure +200mbar of gas pipe

- no dilution of sample gas is required

- integrated gas cooler with condensate draining pump

- direct and continuous measurement, with pressure and temperature compensation

- multiple sampling point monitoring (up to 8 sites monitoring) with one analyzer

- flow restrictor orifice gas inlet for high-pressure site

- with sample gas cut-off and power supply shut-off in case of alarm

- industry compatible rugged design, easy and fastest service design