Description

Features:

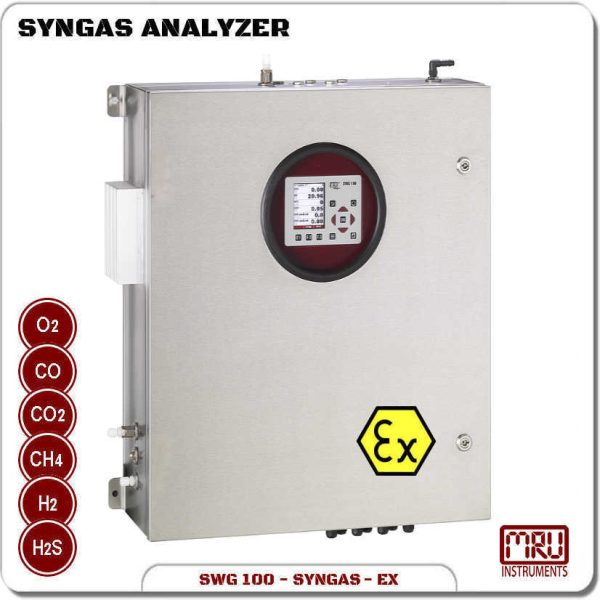

- Designed for use in industrial safe or hazardous area Zone 2, or in areas with an increased safety levels

- Can be installed in outdoor or indoor location

- Can sample dry or wet syngas

- Can sample pressurized or low pressure gas

- Can be used from single or double sampling points.

Applications:

for use in industrial safe or hazardous area Zone 2, or in areas with an increased safety levels

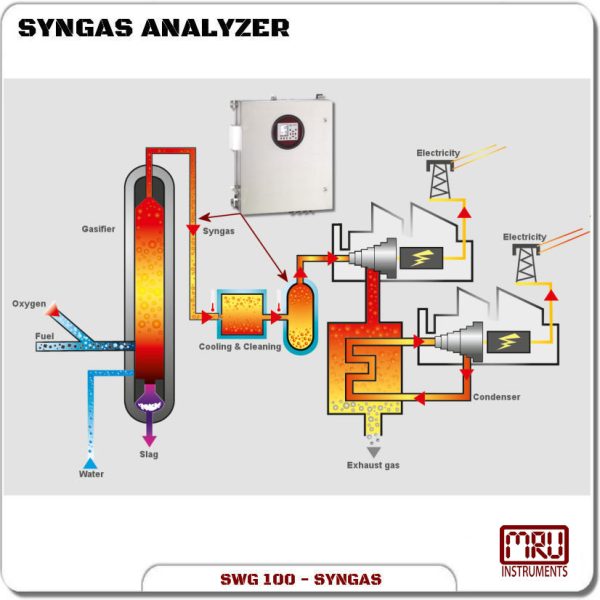

The stationary analyzer for continuous Syngas measurements in ZONE 2

for use in industrial safe or hazardous areas Zone 2, or in areas with an increased safety level.

The analyzer can be installed in outdoor or indoor locations, and it can sample dry or wet syngas, for high or low-pressure applications, low pressurized gas can be used for multiple sampling points.

- For use in industrial safe or hazardous areas Zone 2, or in areas with an increased safety level

- IP65 stainless steel cabinet, also for use outdoors with mandatory sun and rain protection

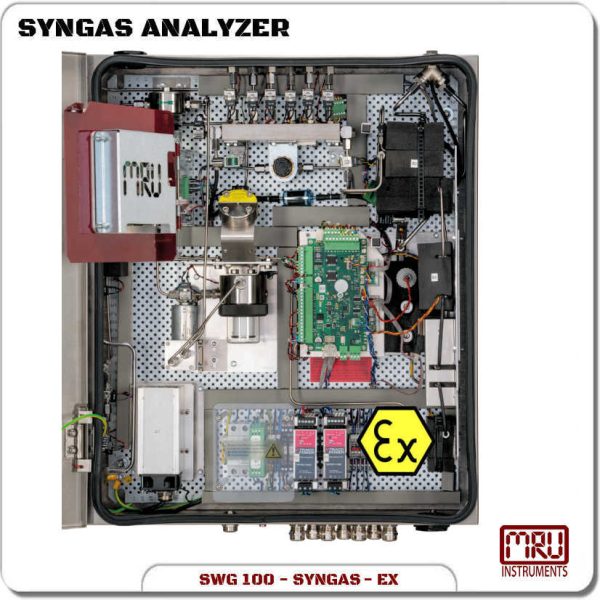

- All stainless steel piping and fittings inside the analyzer

- Accurate measurements, using NDIR and thermal conductivity technology

- Sampling from low suction -100 mbar up to high pressure +200 mbar gas pipe

- Direct measurement (no dilution) of moisture sample gas, with pressure and temperature compensation

- Multiple sampling point monitoring (up to a total of 6 gas ports plus 1x calibration gas port) with one analyzer

- Optionally, up to 3 sample gas ports can be additionally configured as calibration gas port

- Flow restriction at the gas inlet for high-pressure systems with sample gas cut-off in case of system alarm (e.g. gas leakage)

- Note: All sample gas inputs use the same process gas recirculation!

- Industry-compatible rugged design, easy and fastest service design

- Ready to run delivery, minimum installation work

OPTIONALLY

- NDIR bench for CO-CO₂-CH₄ analysis

- (using selective CH₄ measurement)

- O₂ paramagnetic cell measurement

- H₂S electrochemical cell measurement, H₂ immune

- H₂ thermal conductivity detector measurement with cross-interference correction

- RS485 to USB or Profibus or Ethernet converter

- I/O modules with 4 channel 4–20 mA analog output and 2 alarm relays

- Sample gas washing device, for tar-free sample gas

- Different extraction probes are available, certified for ZONE 2

- Different lengths of heated and temperature-regulated sampling lines