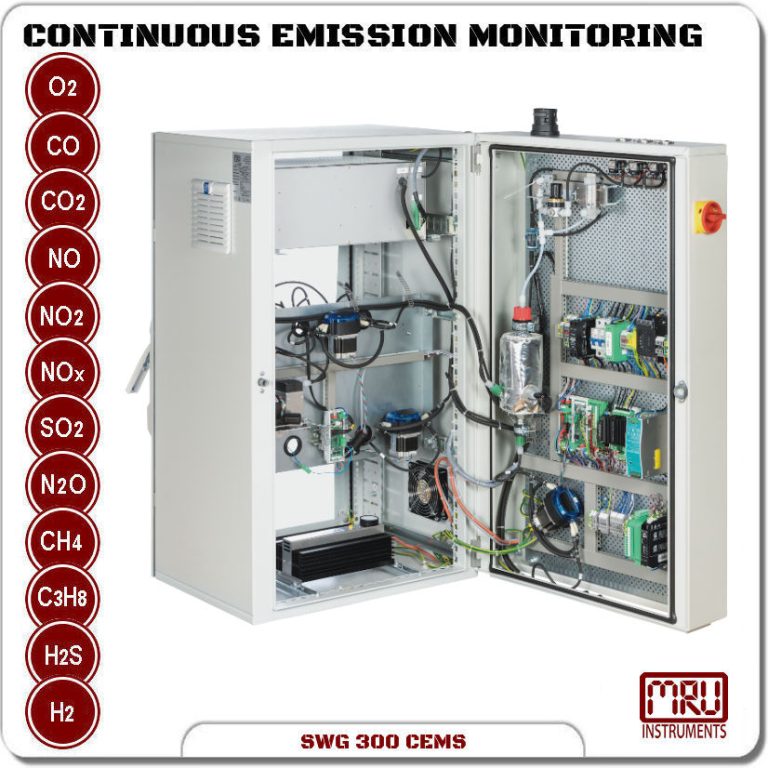

Continuous emission monitoring systems (CEMS) are utilized as tools to screen the profluent gas streams coming about because of burning in modern cycles. CEMS can gauge vent gas for oxygen, carbon monoxide, and carbon dioxide to give data to ignition control in mechanical settings. They are likewise utilized as a way to conserve air discharge principles, for example, the United States Environmental Protection Agency’s (EPA) Acid Rain Program, other US government emanation projects, or state-allowed outflow norms. CEMS ordinarily comprise of analyzers to quantify gas fixations inside the stream, hardware to coordinate an example of that gas stream to the analyzers if they are far off, gear to condition the example gas by eliminating water and different segments that could meddle with the perusing, pneumatic pipes with valves that can be constrained by a PLC to course the example gas to and away from the analyzers, an adjustment, and upkeep framework that considers the infusion of alignment gases into the example line, and a Data Acquisition and Handling System (DAHS) that gathers and stores every information point and can perform vital computations needed to get absolute mass emanations. A CEMS works consistently regardless of whether the interaction it measures isn’t on. They can consistently gather, record, and report outflow information for measure observing, or potentially for consistency purposes.

The standard CEM framework comprises a sample test, channel, sample line (umbilical), gas molding framework, alignment gas framework, and a progression of gas analyzers that mirror the boundaries being observed. Ordinarily observed discharges include sulfur dioxide, nitrogen oxides, carbon monoxide, carbon dioxide, hydrogen chloride, airborne particulate matter, mercury, unstable natural mixtures, and oxygen. CEM frameworks can likewise quantify wind current, vent gas obscurity, and dampness. A checking framework that actions particulate matter is alluded to as a PEMS.

A little sample of vent gas is removed through a siphon into the CEM framework through a sample test. Offices that combust petroleum derivatives regularly utilize a weakening extractive test to weaken the example with spotless, dry air to a specific proportion. Dilution is utilized because unadulterated vent gas can be hot, wet, and, for certain contaminants, tacky. Once diluted to the proper proportion, the sample is shipped through a sample line to a complex from which singular analyzers may remove an example. Gas analyzers utilize different procedures to precisely quantify focuses. Some generally utilized procedures incorporate infrared and bright adsorption, chemiluminescence, fluorescence, and beta beam retention. After analysis, the gas leaves the analyzer to a typical complex to all analyzers where it is vented out of entryways. With MRU Instruments you can get the best emanation checking frameworks according to your industry needs at moderate expenses.